Mineral insulated heating cables

The most durable heating cable in the world

DESCRIPTION

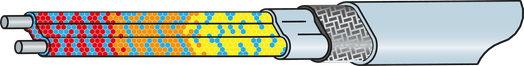

Mineral insulated heating cables, also known as MI heating cables, are semi-rigid and designed to withstand high temperature and high wattage applications. They are used when power and temperature requirements exceed the capabilities of self-regulating and constant wattage cables. The resistance wire is insulated using magnesium oxide, encapsulated in a metal sheath and highly compacted. Magnesium oxide ensures electrical insulation with maximum thermal transfer, and the metal sheath provides extreme durability and protection. MI heating unit consists of the heating cable in the middle, the transition sleeves for hot-cold joint and the cold ends with connecting cables and end fittings, on both sides. Since the units consist of a series resistor, theoretically any power-voltage-length configuration can be produced. MI cable can be used in both ordinary and hazardous environments.

APPLICATIONS

- Tanks, containers, vessels, drums

- Material transport, hoppers

- Pipes, valves, flanges, metal tubes

- Radiant heaters, furnaces

- Surface heating, plate heating

- Pump heating

- Loading arms

Technical data

Type of heating | Contact heating |

Material | Sheath: Stainless steel - CrNi, Copper-nickel - CuNi, Copper - Cu |

Dimension | Diameter: Ø3.2-Ø6.5mm |

Assembly | Adapted for the application |

Connection | Connections at both ends |

Design | Round cross section |

Others | Voltage: Acc. to customer specification Specific resistances: Sheath temperature: Dielectric strength: 2000V |

BENEFITs

- High surface load

- Temperature resistant, UV resistant

- Resistant to aging and corrosion

- Easy install due to ease of shaping

- Can be individually formable

- High diversity of specific resistances

- Extremely durable, long lasting

- High strength, rugged construction