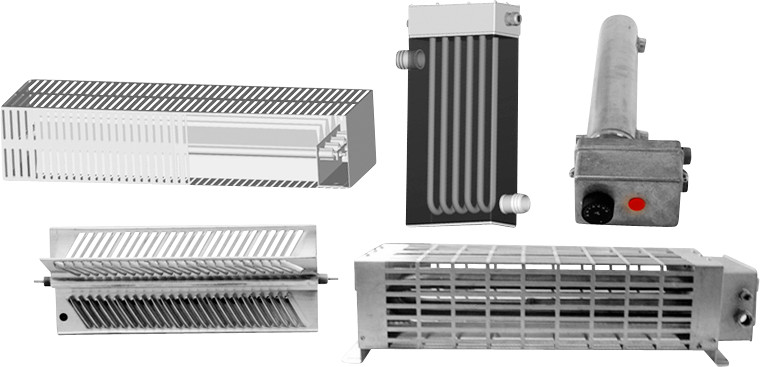

Aluminum housed resistors

Maximum heat conduction or forced air convection

DESCRIPTION

Aluminum is a metal with characteristics that make it an ideal choice for high-power resistors. The Aluminum housing is anodized, making it non-corrosive, lightweight yet durable. For maximum heat transfer, these resistors have a housing with deep slats. Resistors with an aluminum housing provide excellent heat conduction. The resistors cool via natural convection. Using forced air cooling can improve cooling and operation at higher power ratings.

APPLICATIONS

- Brake resistors

- Energy dumping

- Charging and discharging resistors

- Wind power turbines

Technical data

Material | Aluminum |

Dimension | Standard range or acc. to customer specification |

Assembly | Free standing |

Connection | Cables |

Design | Convection cooled |

Others | Power range: from 100W to 50kW Protection class: from IP00 to IP66 |

Benefits

- Excellent heat conduction

- Resistance to environmental conditions

- Good vibration withstand capability

- High IP ratings