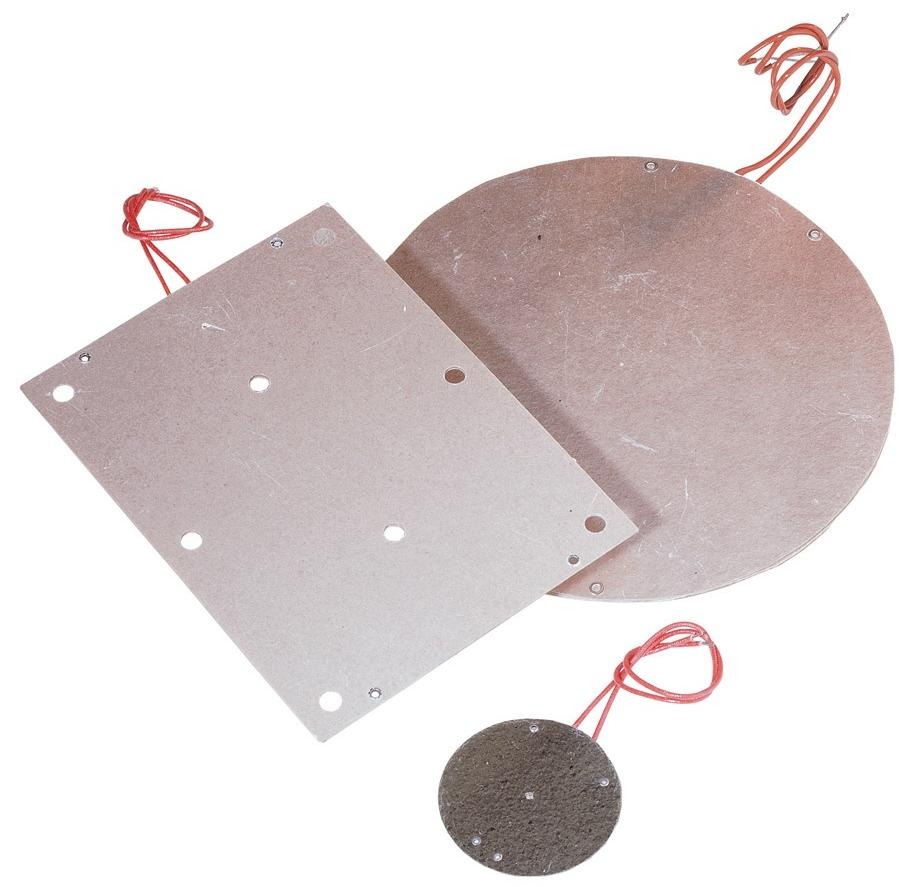

PTC elements

Positive temperature coefficient technology

DESCRIPTION

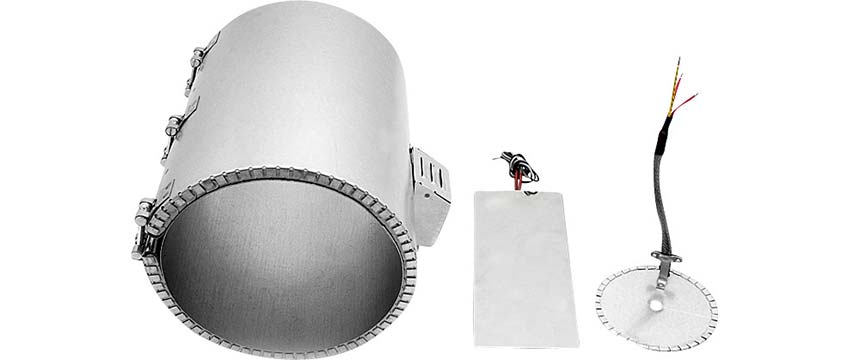

PTC elements are used as heating sources in air heaters, drying units and compartment heaters for cars and trains. PTC elements consist of PTC thermistors and aluminum strips joined by brazing or gluing. The PTC element can be mounted in a frame of heat-resistant plastic or integrated a specific application.

PTC elements offer many advantages such as quick and uniform heating and no power variation despite the presence of air flow. They have a self-regulating function and a long life-time. There is no risk of overheating. PTC technology is also used in tubular and flexible elements.

APPLICATIONS

- Compartment heaters

- Dehumidifiers

- Radiators, Towel dryers

- Air heaters, Fan heaters, Hot air curtains

- Warming plates

- Glue guns

- Heating systems for vehicles

- Tumble driers, Hand dryers

- Cabinet heaters

- Defrosting, Evaporation of condesed water

Technical data

Type of heating | Forced convection - air heating |

Material | PTC thermistor: Ceramic BaTiO3 |

Dimension | Standard range or acc. to customer specification PTC air elements: 120x53x22mm, 120.5x70.5x22mm, 173x70.5x22mm, 122x115x20mm, 138x138x44mm PTC water elements: Ø12x121mm, Ø12x171mm, Ø12x221mm, Other lengths: 50-300mm, acc. to customer specification |

Assembly | Assembly in a frame of heat-resistant plastic |

Connection | Tab terminals |

Design | Standard range as well as custom made products |

Others | Switching temperature: Curie set point Min. 50°C, Max. 260°C |

benefits

- Rapid heating

- Self-regulating function

- Heating power controlled by the air flow

- Uniform heating without power variations

- No risk for overheating

- No overheating protection and regulation needed

- Long service life

- Can be installed in any direction

- Compact construction

- Large heat transferring surface

- Energy saving