Finned elements

Increased area and reduced temperature

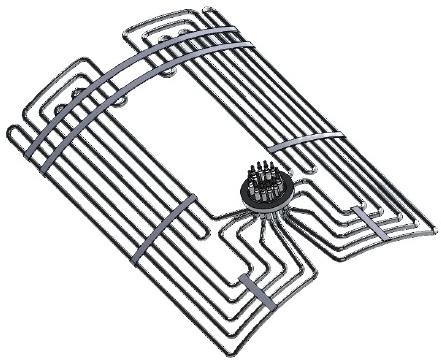

DESCRIPTION

Elektrotermija produces tubular finned heating elements which consists of standard round tubular heating element and stainless steel strip that is coiled arround the element. This enlarging of heating surface reduces working temperature of the element, extends working life time or on the other hand could lead to reducing diameter of the element or overall dimensions of the assembly. Heat is transfered by forced convections using fans and very rarely these elements are used without fans. Elements can be straight (I shape) or bent in standard shapes U, M or multiple M, for other shapes please consult factory. When designing finned elements it is important to specify working temperature, air velocity (or air flow), dimesions of available space and application. Finned heaters are usualy produced with electrical connections M4 and mechanical connections M14x1.5 , other connections upon request. We can produce elements with extended cold zone (cooling zone), double mechanical connections, unheated area at U bent part and lot of other special executions and features.

APPLICATIONS

- Radiators, Convectors

- Packaging machine, Heat shrinking machines

- Duct heaters

- Heating curtains

- Sterilizers

- Ovens

- Body side heaters for trains

Technical data

Type of heating | Forced convection |

Material | Tube material - Stainless steel: AISI 309 / EN1.4828 as an alternative: |

Dimension | Tube diameter: Ø6.5, Ø8.5, Ø10, Ø12, Ø14, Ø16, Ø18mm |

Assembly | Nipples, fixing plates, etc. acc. to customer specification |

Connection | M4, M5, M6, cables, tab terminals, round pins |

Design | One-side or two-side connection Standard bending shapes: I, U, M, multiple M Different shapes acc. to customer specification |

Others | Voltage: Max. 480V, for higher values consult factory |

BENEFITS

- Reduced surface temperature

- Increased radiation area

- Compact design of application possible

- High radiation power