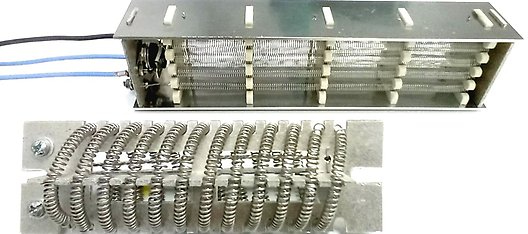

Cage rod ELEMENTS

Shaped heaters supported on ceramic plates

DESCRIPTION

Cage rod elements consist of metallic heaters and electrically non-conductive parts such as ceramic plates or spacers. These ceramic plates serve as insulation between heater and radiant tube. Also, holes and grooves in the ceramic plates receive the heaters, which in this way are kept electrically insulated from each other. The central rod is necessary to bind the ceramic parts together.

Heaters can be made from CrFeAl alloys or from NiCr alloys, depending on working conditions, temperature and atmosphere. Cold ends can be created by inserting ceramic parts between electrical connection and heating part. To prevent the heater from overheating, it is recommended to use one safety thermocouple per element or at least one per heating zone on furnace. Power depends on the element diameter, length and temperature.

APPLICATIONS

- Melting processes and casting plants

- Enameling, holding and other industrial furnaces

- Heat treatment applications

- Steel and aluminum industry

- Automotive and general engineering industry

Technical data

Type of heating | Radiation |

Material | Heater: FeCrAl alloys or NiCr alloys |

Dimension | Standard diameter: Ø68mm, Ø168mm |

Assembly | Vertical or horizontal installation position |

Connection | Terminal rods for electrical connection, with or without thread |

Design | Acc. to customer specification |

Other | Power: 5000-20000W |

Benefits

- Can be used inside tubes or as stand-alone elements

- Can be installed both horizontally and vertically

- Long service life

- Savings in replacement and maintenance costs

- Higher power output compared to conventional heaters