.jpg)

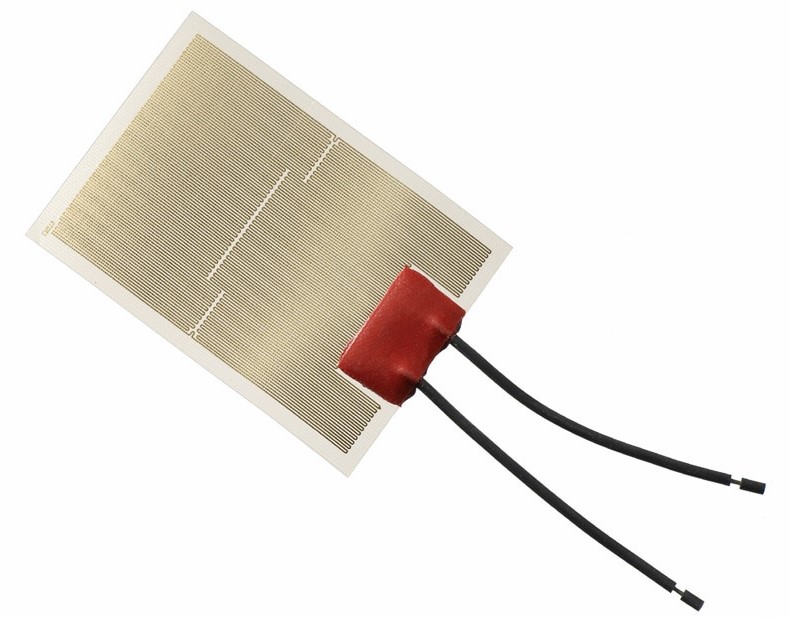

Flexible elements

Possible to use in almost any application

DESCRIPTION

Flexible heating elements offer many advantages such as even heat distribution, fast heat-up, compact design, low weight and power density. This makes the field of application broad and diversified. They can be designed in almost any shape and the large choice of insulation materials makes it possible to use flexible elements in almost any application. The even heat distribution also makes the flexible element energy efficient.

Heating element inertia improoves the heat accumulation and provides a longer cooling time. It also means longer time is needed to heat up the element. Various flexible elements mounted on the front panel can here offer a perfect combination, providing instant heat radiation evenly distributed on the front panel, until the main heat source has reached the set temperature.

APPLICATIONS

- Medical and laboratory instruments

- Heat pumps, compressors and crannkcases

- Barrel, drum, pail or cylindrical vessel heaters

- Food heating applications

- Underfloor heating

- Bathroom mirror heaters

- Heating panels, ceiling heaters

- Various industrial applications

- Preventing ice and condensation

- Refrigeration and evaporation systems

Technical data

Type of heating | Contact heating |

Material | Silicone |

Dimension | Almost without limits Standard range or acc. to customer specification |

Assembly | Adhesive |

Connection | Cables |

Design | Many types of configurations to fit the size and shape required Multiple circuits or voltages in the same element Possibility to add thermostat, safety fuse, thermistors or temperature sensors |

Others | Power: Max. 1500W Safety acc. to EN 60335-1 |