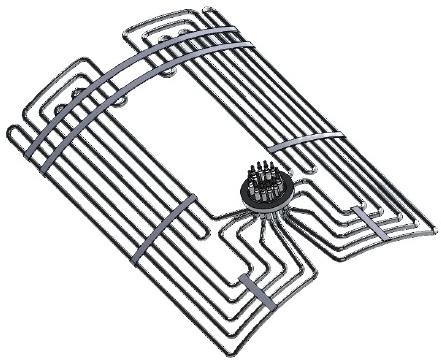

Tubular air elements

The most popular for air heating and radiation

DESCRIPTION

Round tubular heating elements for air application are made in straight or bend shape according to customers needs. We produce elements from stainless steel tubes, high quality MgO insulation and resistive coil. The resistive coil is made from NiCr or FeCrAl alloy and placed in the center of tube, afterward compacted with MgO which provides even and fair heat transfer. At the ends of the element are terminal pins (cold ends) which length may vary. In order to prevent penetration of moisture inside of the elements, elements are sealed with appropriate silicones or epoxy. We produce dark annealed stainless steel elements thus allowing bending and eliminates stresses inside protective tube.

Elektrotermija produces air tubular electric heating elements with mounted electrical and mechanical connections. We have wide range of various flanges, nipples, mounting plates and brackets for assembling of the elements to the devices. For electrical connection we provide standard electrical tabs, threaded connections or lead and cable connections.

Surface load represents ratio between power and heating surface of the element and this characteristic is essential when designing tubular heating element. Maximum surface load depends on working conditions, temperature, on/off cycles, regulation etc. We will be glad to share our knowledge and experience with you and to offer/design the best solution. We are specialized for small to medium series of tubular heating elements for air and gases.

APPLICATIONS

- Household appliances

- Industrial furnaces, dryers

- Ovens, grills, frying tables

- IR-heaters, saunas

- Radiators, convectors

- Train compartment heaters

- Packaging machines

Technical data

Type of heating | Forced or natural convection |

Material | Tube material - Stainless steel: |

Dimension | Tube diameter: Ø6.5, Ø8.5, Ø10, Ø12, Ø14mm Minimum straight length: 300mm Maximum straight lengths: Length tollerance: ±1.5%, tighter upon request Other dimensions avaliable upon request |

Assembly | Fixing in the object with flanges/nipples, fixing plates, etc. acc. to customer specification |

Connection | M4, M5, M6, spot welded cables, tab terminals, round pins |

Design | Custom made elements as per customer request, drawing, sample, idea... Different shapes acc. to customer specification Thousands of different standard types produced so far |

Others | Voltage: Max. 480V, for higher values consult us Surface load: Max. 6 W/cm², for higher values consult us |

Benefits

- Can be shaped to meet most demanding requests

- Low tool cost for new production

- Wide selection of fixing and connection devices

- Easy installation

- High working temperatures

- Long life product

- Low weight