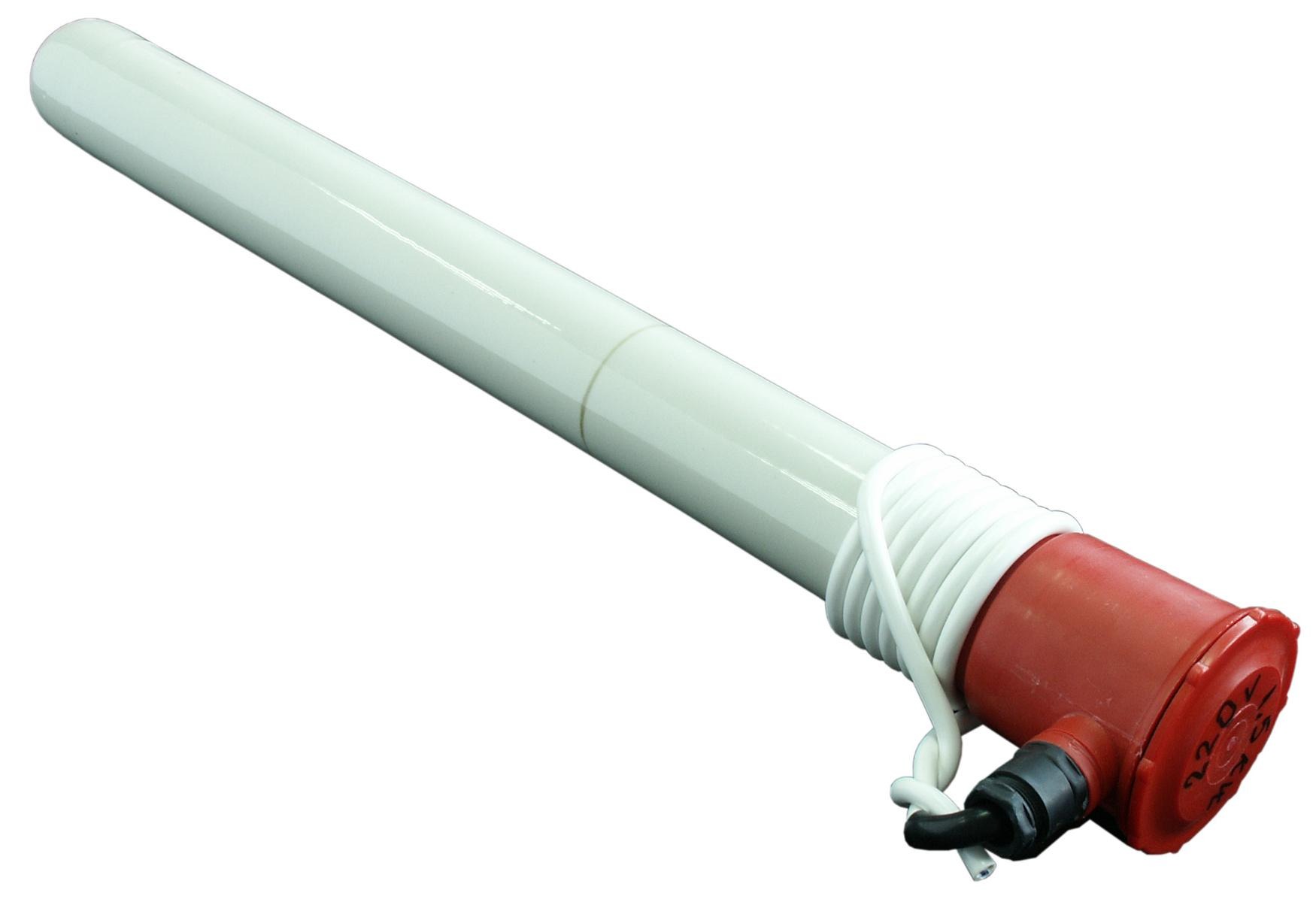

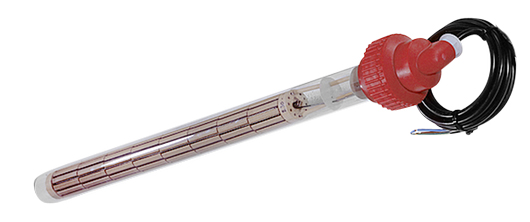

Titanium tube

High strength and heat resistance

DESCRIPTION

This type of heaters are manufactured in protective tubes made of titanium. They are delivered with protective caps and connection cables. The main advantage is the possibility of changing the ceramic cartridge without changing the protective tube. They are used for heating of fluids in electroplating baths and tanks. The heaters are immersed directly in working solution. Titanium tube provides stability of heater when immersed in fluid. They are resistant to mechanical damage and can operate short term without fluid and in case of voltage changes. Titanium tubes are resistant when operating in alkaline environment. Sulfuric and hydrochloric acid can damage titanium tubes.

APPLICATIONS

- Nickel plating

- Copper plating

- Intaglio and textile printing

- Various types of baths, vessels and tanks

- Chemical and electro-chemical processes

Technical data

Type of | Liquid heating |

Material | Titanium tube, EN 3.7035 Grade2, ASTM B338 |

Dimension | Standard range or acc. to customer specification Diameter of tube: Ø50.8mm |

Assembly | Vertical position in the bath |

Connection | PVC cable 2m included |

Design | Standard range or acc. to customer specification With ceramic heater inside tube |

Other | Voltage: 230V, 400V, 3x400V Regulation: External thermostat, Liquid level controller Alternative product: Tubular heating elements with titanium tube |

Benefits

- Resistant to mechanical damage

- Changing the heater without changing the tube

- Suitable for operating in alkaline environment

- High strength and high heat resistance