CONSTANT WATTAGE HEATING CABLES

For frost protection and temperature regulation

DESCRIPTION

Constant wattage heating cables are divided into zones and can be cut to any desirable length. They have a constant wattage per meter throughout the entire length of the cable. That means that total power depends only on required length of heating cable. Elektrotermija offers these type of cables for temperatures up to 180°C and specific wattages from 10W/m to 50W/m.

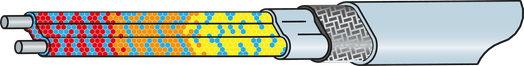

Heating cables of constant power are produced by winding of heating wire around two parallel conductors . The conductors are insulated with silicone rubber. At the distance of each 500mm, around 10mm of insulation is removed thus making a contact between heating wire and load or neutral conductor. Outer layer of silicone insulation guarantees good flexibility and resistance to high temperatures. Metal braid gives protection from mechanical damage, improves heat transfer and can be used for grounding.

The heating cables must not cross one another and a thermostat must always be used to control the temperature. We supply a wide range of thermostats and accessories for heating cables.

APPLICATIONS

- Air-Conditioning - heating and temperature maintaining of containers, tanks, reservoirs, bunkers

- Constructions - freezing protection of metal and plastic pipes, valves and fittings; temperature maintaining of steam, oil fuel and water pipelines

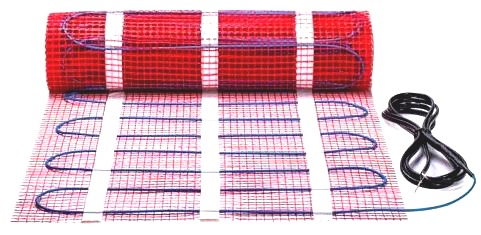

- Civil engineering - removing of snow and ice from: roofs, water shoots, drains, skylights, staircases, pavements, ramps; under floor heating of residences, business offices

- Refrigeration - prevention of condensation on cooling cabinets; defrosting of evaporators; door heating in cold storages; under floor heating of cold storages; compressors

- Various purposes - heating of aquariums, terrariums, glasshouses; agriculture applications, growing of vegetables, flowers and mushrooms, breeding of animals; electric blankets, telecommunication equipment, satellite antennas

Technical data

Type of heating | Defrosting, frost protection |

Material | Heating wire: Resistance alloy NiCr, CuNi, FeCrAl |

Dimension | Cross section, without braid: 7.5x5.2mm Heating length: Acc. to customer specification Bending radius: Min. 20mm |

Assembly | Adapted for the application |

Connection | Flexible cables acc. to customer specification |

Design | With or without final outer jacket - transparent silicone rubber insulation. |

Others | Specific power: 10, 20, 30, 40, 50W/m² Max. operating temperature: 180°C Dielectric strength: 1500V/1s Accessories: Capillary, ambient or contact thermostats, Regulators, Sensors, Control cabinets |

Benefits

- Excellent flexibility

- Good mechanical and temperature resistance

- Adaptability to different heating surfaces, easy to install

- Small cross section

- Connection on one side

- Breakdown on one heating section does not cause a breakdown of entire heating cable

- No current peaks at startup

- Feasibility of cutting off cable to required length

- Without visible signs of aging during exploitation period