teflon COATed heaters

Excellent chemical resistance

DESCRIPTION

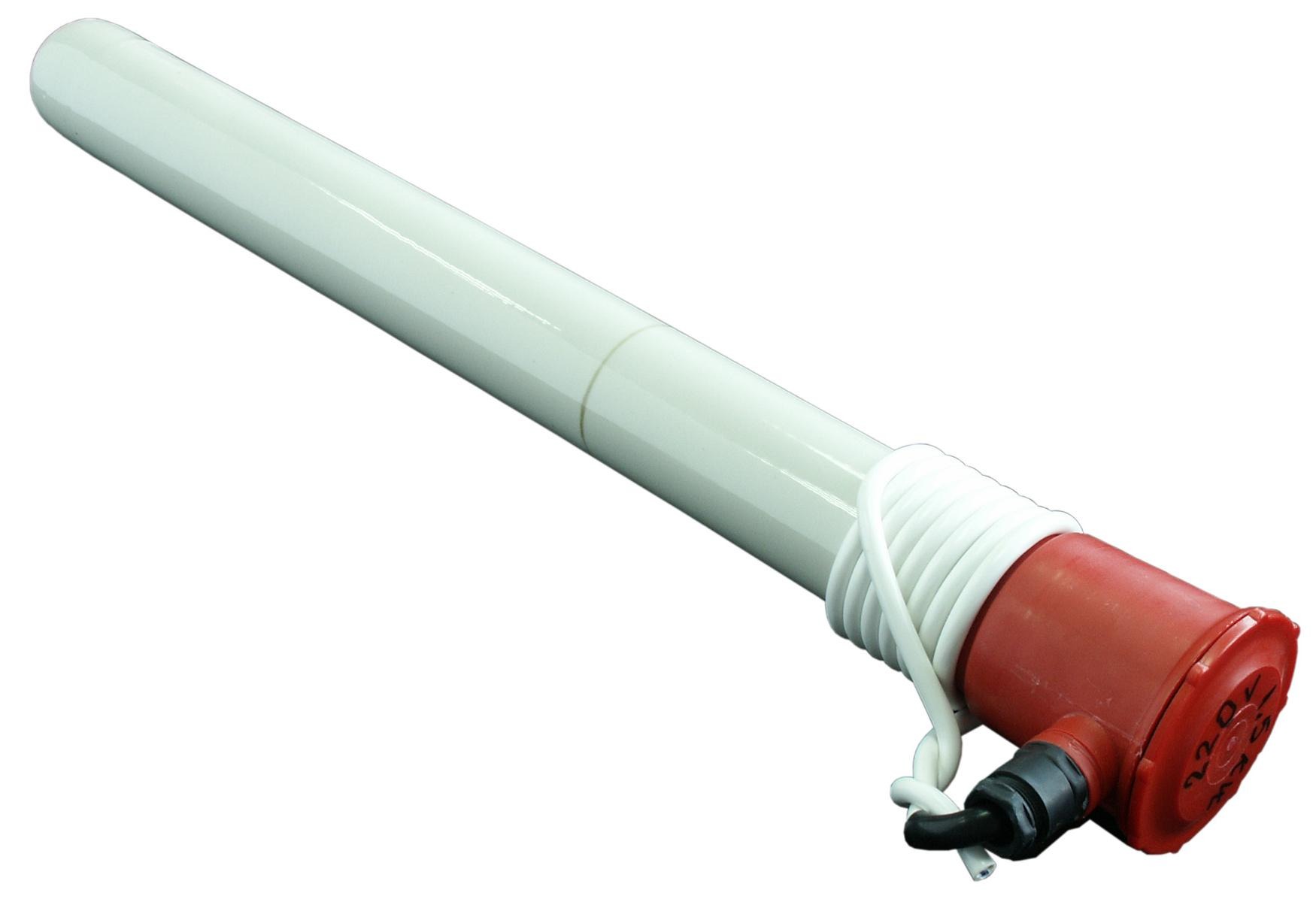

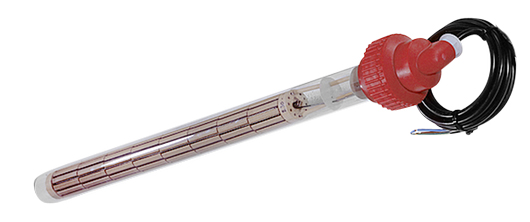

Tubular galvanic heaters with teflon (PTFE) coating are used for heating of fluids in electroplating baths and other industrial processes. Heaters consist of connection head, tubular heating element, PTFE coating and connection cable. These heaters combine versatility of tubular elements and excellent chemical resistance of teflon. They are shaped according to baths and installation method. Heated part must be fully immersed in fluid, while connection head must be out of fluid and away from vapors and steams. Special three phase executions with 3 or 6 elements at one terminal box. Liquid level controller and thermostat should be mounted on the bath.

APPLICATIONS

- Nickel plating, chemical nickel plating

- Chrome plating

- Phosphating

- Electro polishing of stainless steel and aluminum

- Electrolyte with F anion

Technical data

Type of | Liquid heating |

Material | Tube material - Stainless steel: Teflon (PTFE) coating Epoxy resin connection head |

Dimension | Standard range or acc. to customer specification Element diameter: Ø8.5mm, Ø10mm Connection head Ø60x44mm PTFE coating up to 1mm |

Assembly | Vertical position in the bath |

Connection | PVC cable 2m included |

Design | Tubular heating element with teflon (PTFE) coating Different shapes acc. to customer specification |

Other | Voltage: 230V, 400V, 3x400V Regulation: External thermostat, Liquid level controller Alternative product: Catridge heaters with PTFE coating |

Benefits

- Excelent chemical resistance

- Suitable for heating of almost all fluids

- Different shapes available

- Dimensions and power upon request