RUBBER VULCANIZING PLATES

Mainly used to repair rubber conveyor belts

DESCRIPTION

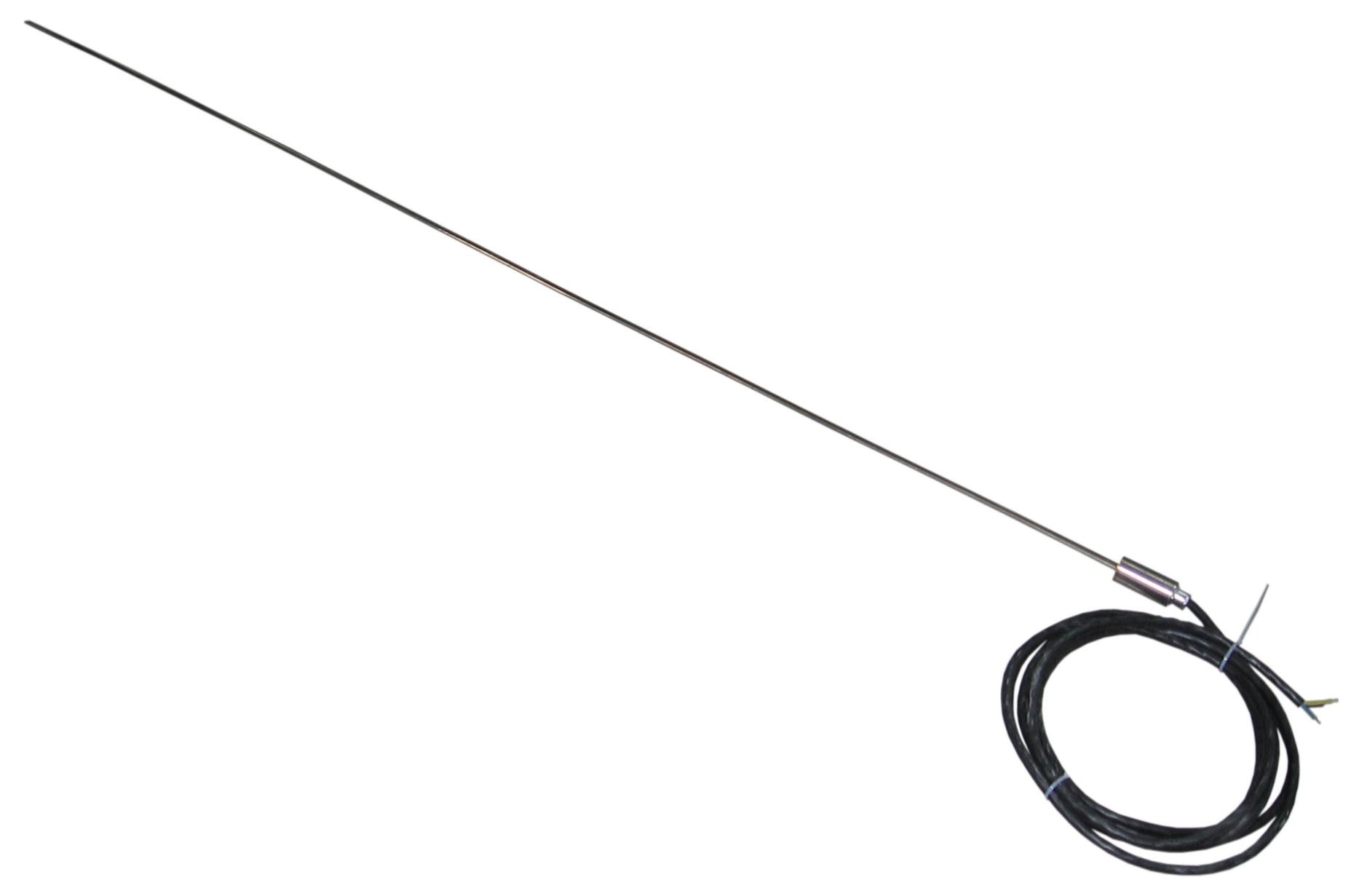

The product consists of one pair of plates (upper and lower) whose heating surfaces are facing each other. Plates are placed on the plate supports - crossbeams. For manipulation and mooving during installation, there are four rings through which the rope can be passed. They are used in the process of vulcanization of rubber conveyor belts. Pre-prepared joints are placed between the heating surfaces on the plates, heated to a given temperature and pressed using hydraulic pressure system. The heating temperature can be adjusted and depends on the requirements of the vulcanization process. It is usually from 150°C to 160°C. The plates are powered by electricity using cables with special robust electrical plug connections. Thermocouples are connected to the temperature controllers with special connectors and cables. Control cabinet with connectors, digital temperature display and signal lamps, controls the operation of one pair of plates during vulcanization.

APPLICATIONS

- For rectangular splicing of conveyor belts

- For rhombic splicing of conveyor belts

- For repairing of longitudinal rips and damage to belt edges

- For repairing of spots and punctures on conveyor belts

Technical data

Type of heating | Contact heating |

Material | Plate: High quality aluminum alloy AlMg4.5Mn |

Dimension | According to customer specification Length: 1360-2245mm Example 1: 600x600x55mm, 3000W |

Assembly | Fixed on plate supports - crossbeams |

Connection | Special robust electrical plug connections |

Design | Plate-type construction (heating elements pressed into the grooves) Rhombic shape: 16°42’ or 22° With built in PT100, PT1000 or thermocouple Type K |

Others | Voltage: 230V single phase, 3x400V three phase |

Benefits

- Robust construction

- Long service life

- High level of safety

- Quick heat up and cool down time

- Optimum temperature distribution

- Quick assembly and disassembly