cartridge heaters high density

Finest power distribution and highest surface load

DESCRIPTION

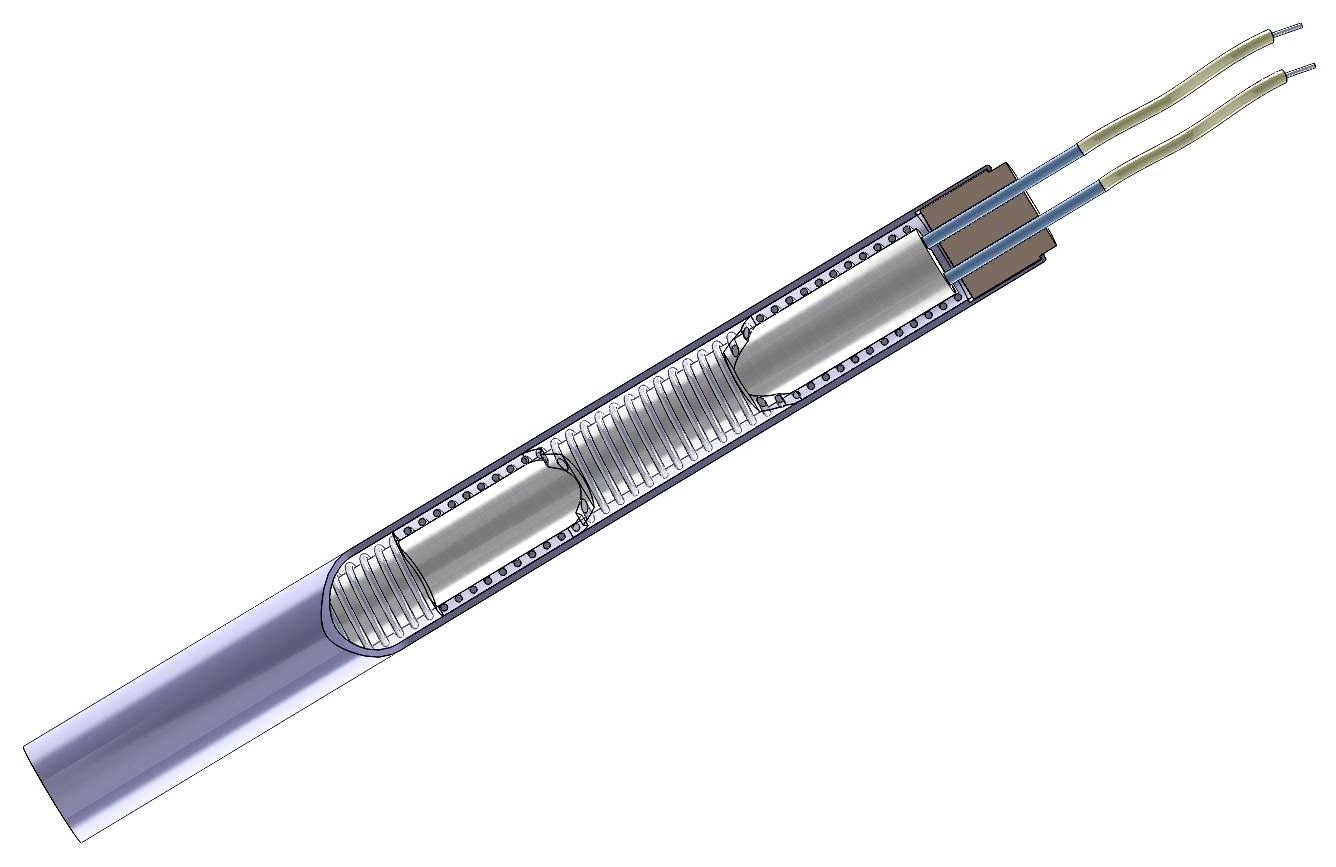

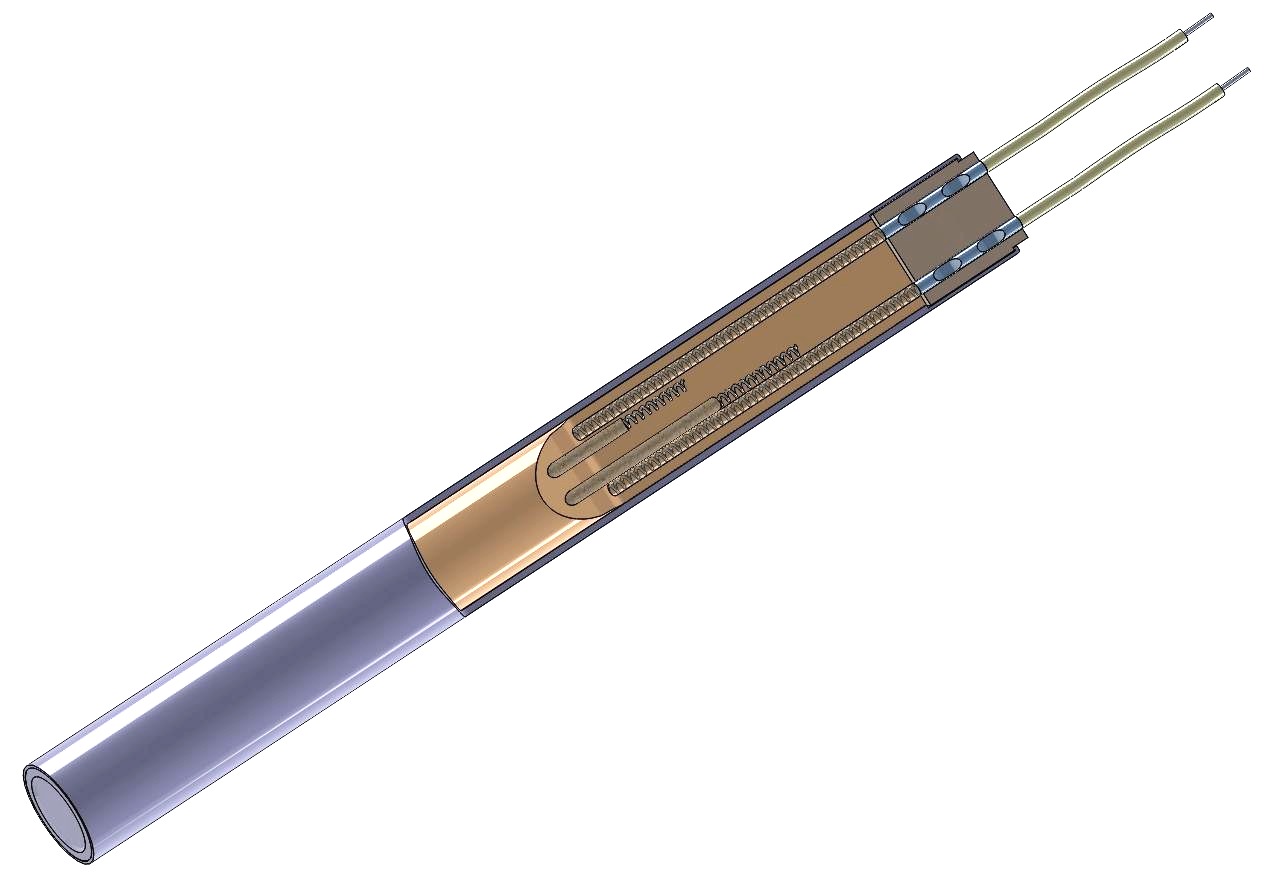

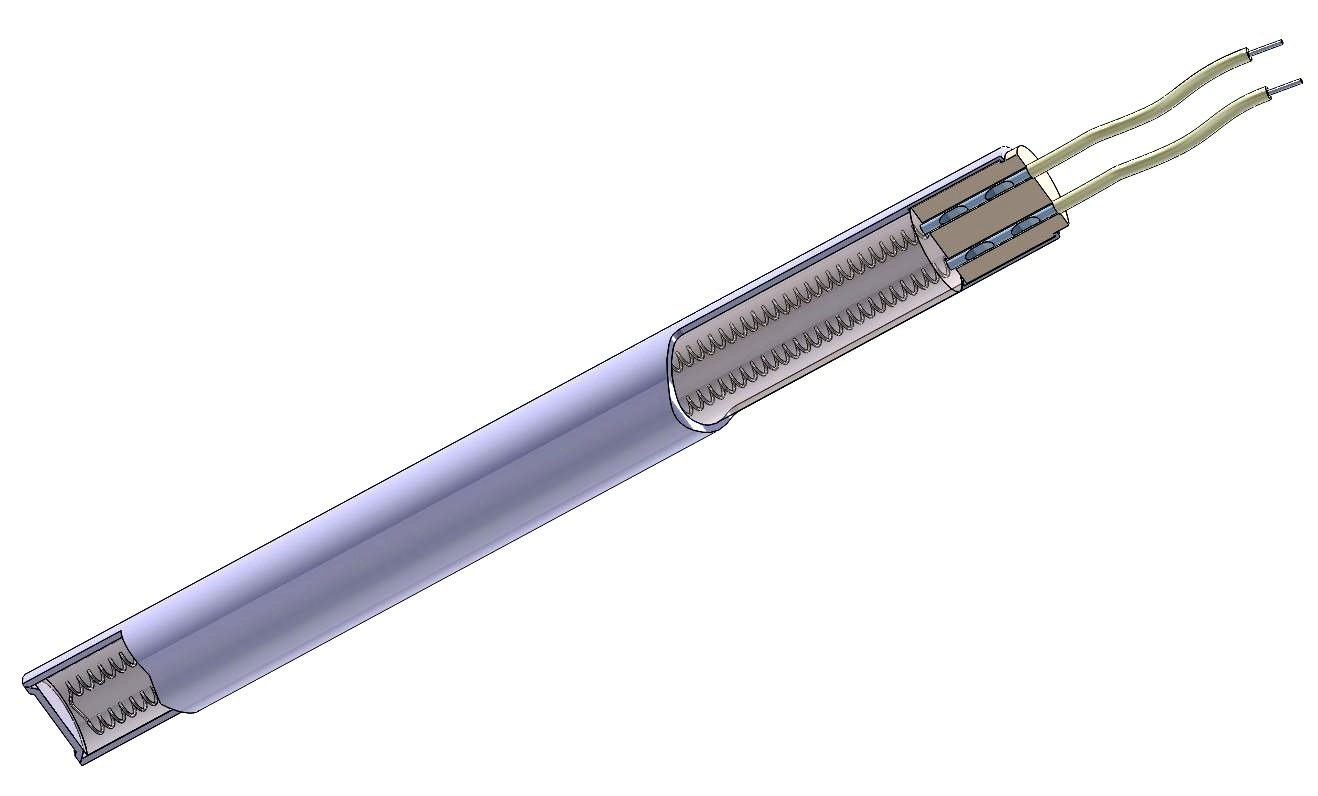

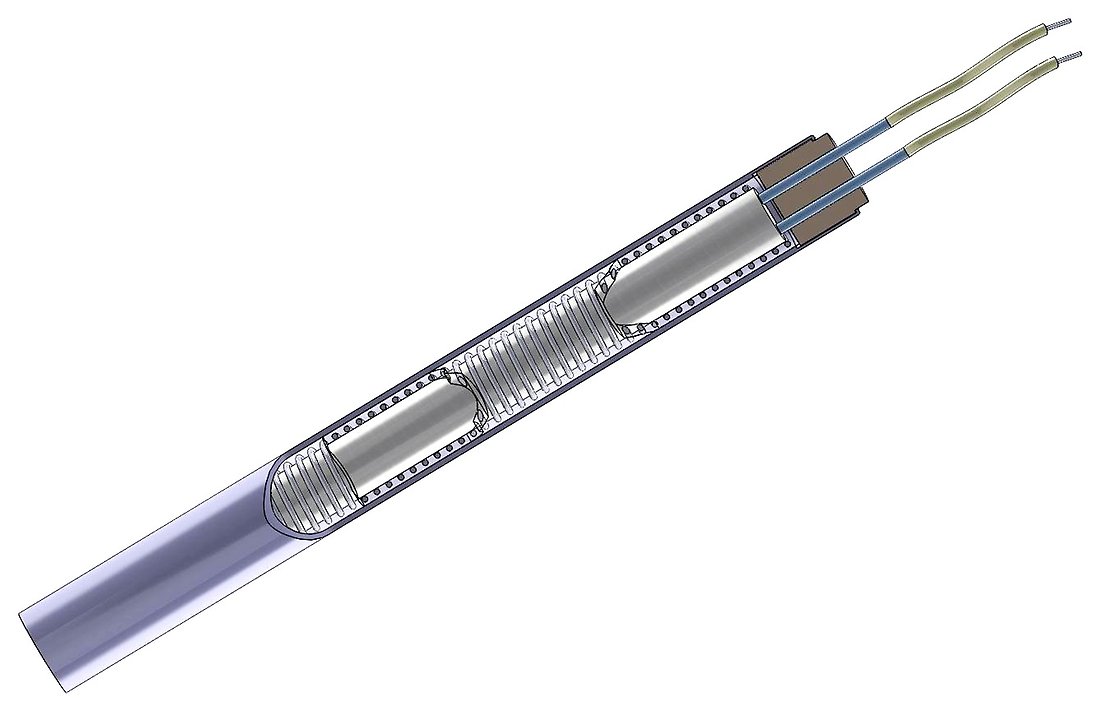

High density cartridge heaters are modern and improved version of standard cartridge heaters. They are designed to withstand high surface loads, thus allowing production of elements with high power and small dimensions. Advanced technology and precise production makes them reliable and indispensable for numerous industrial applications. Ni-Cr resistance wire is wound on MgO core, close to the inner wall of stainless steel protective tube. This design allows excelent heat transfer from wire to tube. Special attention must be paid when preparing holes for heaters (H7 tolerance) and when inserting heaters (heat transfer paste, no gaps). Due to a wide range of semi-finished high density cartridge heaters on stock, we can ship finished products within few days.

APPLICATIONS

- Plastic and rubber industry

- Footwear and leather industry

- Automotive industry

- Medical and laboratory technology

- Woodworking machinery

- Foundries

- Machine building industry

- Pellet burners

Technical data

Type of heating | Heating of tools with hole matching H7 |

Material | Tube material: Flange or nipple material: |

Dimension | Diameter: Ø5mm - Ø25mm (Ø1/4" - Ø1") Standard diameter: Ø6.5, Ø8, Ø10, Ø12.5, Ø16, Ø20mm (Ø1/4", Ø5/16", Ø3/8", Ø1/2", Ø5/8", Ø3/4") Inactive length at the connection end: Min. 15mm |

Assembly | Flanges, plates, rings Threaded nipples: |

Connection | Smooth rigid pins (naked or insulated) Flexible cables for high temperatures: Additional cable protection: |

Design | Standard range or acc. to customer specification Straigth cable outlet (inner contact, outer contact, contact in ceramic bead) Protective connection heads or boxes Built in thermocouple (Type J or Type K, grounded or insulated) |

Others | Surface load: Max. 30W/cm² Diameter tolerance: -0.03/-0.10mm Dielectric strength: 1250V |

Benefits

- Possible high surface load

- The most precise distributed wattage profile

- Good heat transfer

- Compact and robust design

- Easy mount and dismount

- Wide range of dimensions

- Special connections and designs are available

- Thermocouple can be built-in