Micanite elements

Fast and uniform contact heating

DESCRIPTION

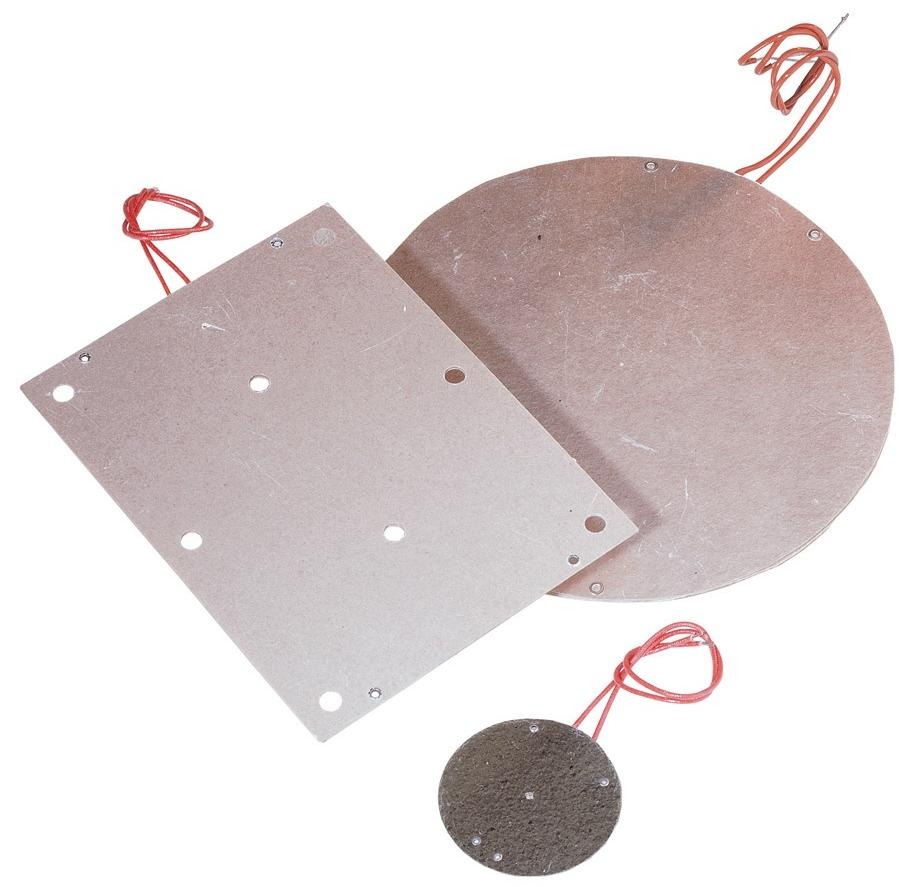

Micanite elements are typically used for contact heating of tools and for indirect heating of fluids in different types of vessels. Micanite is an excellent insulation material based on mica, which can be cut, punched or shaped to suit different applications. It can be rigid or soft in order to fit the application.

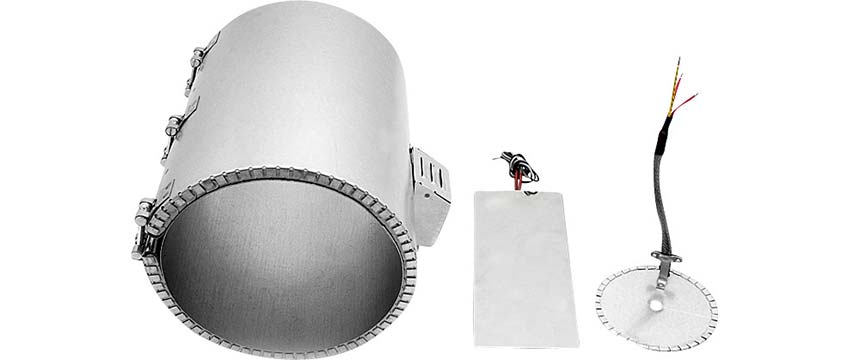

The micanite element is a resistance ribbon or wire, sandwiched between layers of mica. For use at temperatures below 100°C, it works perfect as a stand-alone heater. Higher temperatures require proper support and even pressure to provide good heat transfer. For example, it can be uniformly clamped between two metal plates. Micanite elements enclosed in flat or round metal sheeting are called ring or band heaters.

APPLICATIONS

- Protection against cold

- Tool heating

- Drying equipment

- Bread toasters

- Heating plates

- Containers

- Frost protection

- Packing, strapping and sealing equipment

- Food service appliances

- Radiators, heating panels

Technical data

Type of heating | Contact heating |

Material | Micanite |

Dimension | Acc. to customer specification |

Assembly | Fixing to the object |

Connection | Cables, tab terminals, screws and nuts, nickel wires with ceramic beads or silicon rubber hose |

Design | Acc. to customer specification |

Others | Operating temperature: Max. 400°C |

BENEFITS

- Can be shaped to fit the application

- Compact design

- Fast warm up

- High working temperatures

- Can be used assembled in open air

- Low moisture absorption