cartridge heaters Low density

Primarly used for tools or solid bodies warming

DESCRIPTION

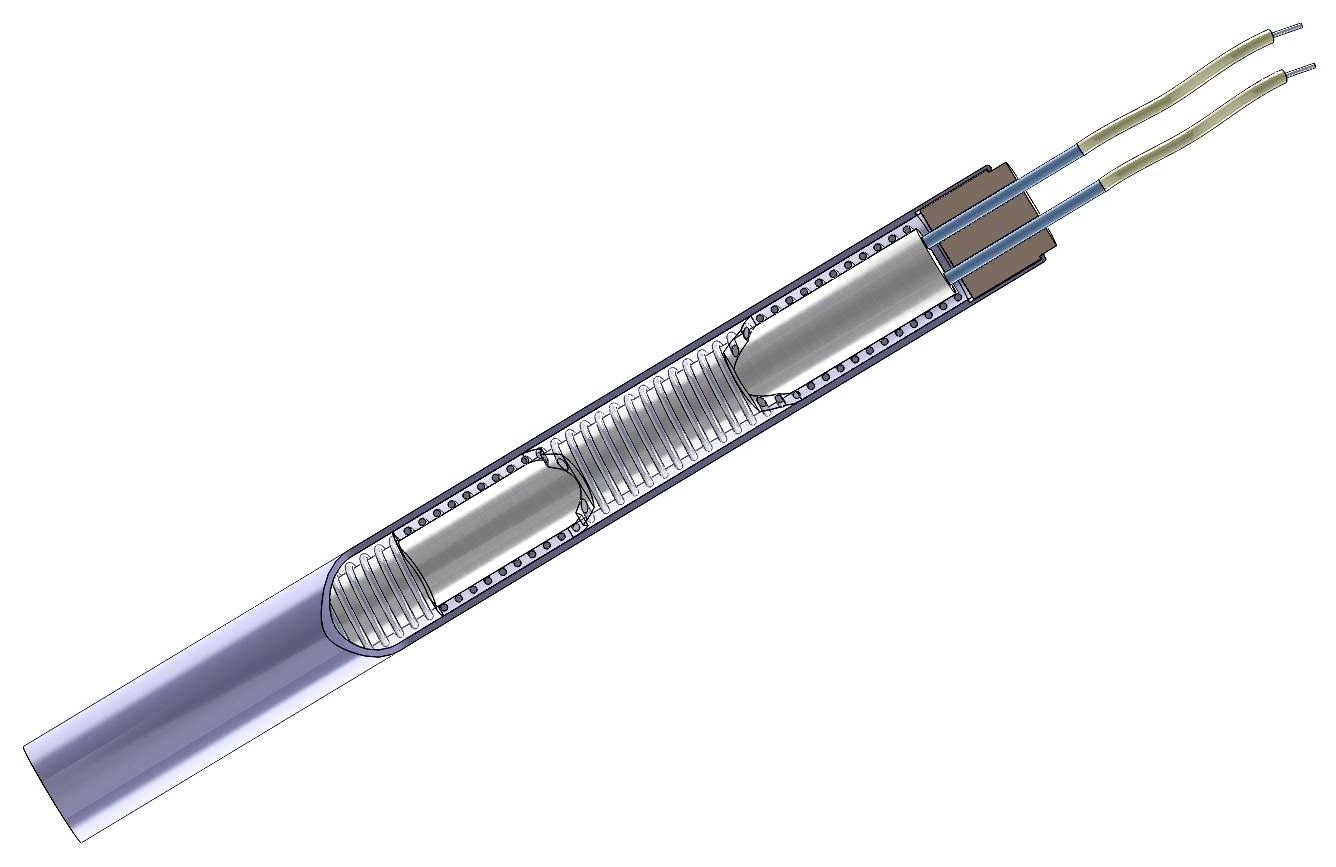

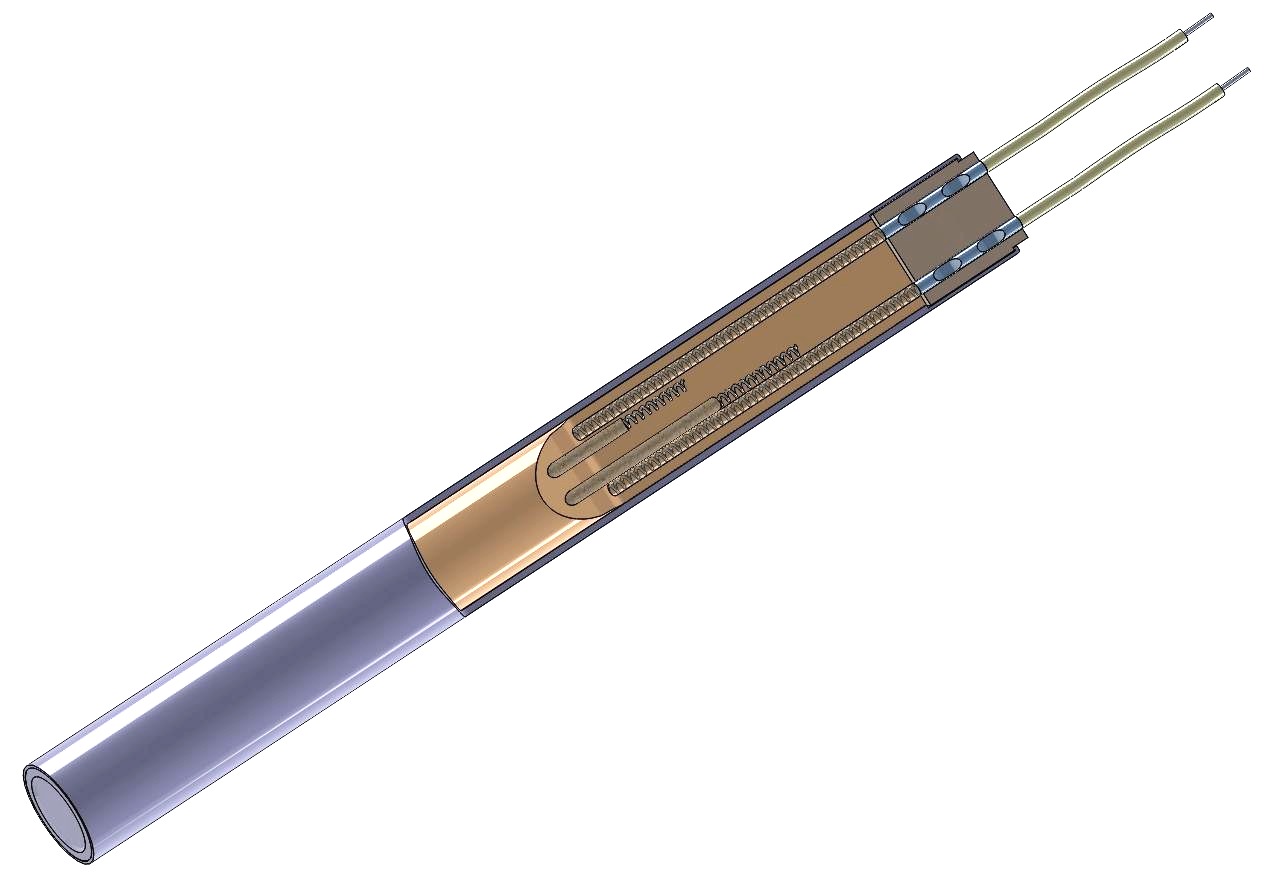

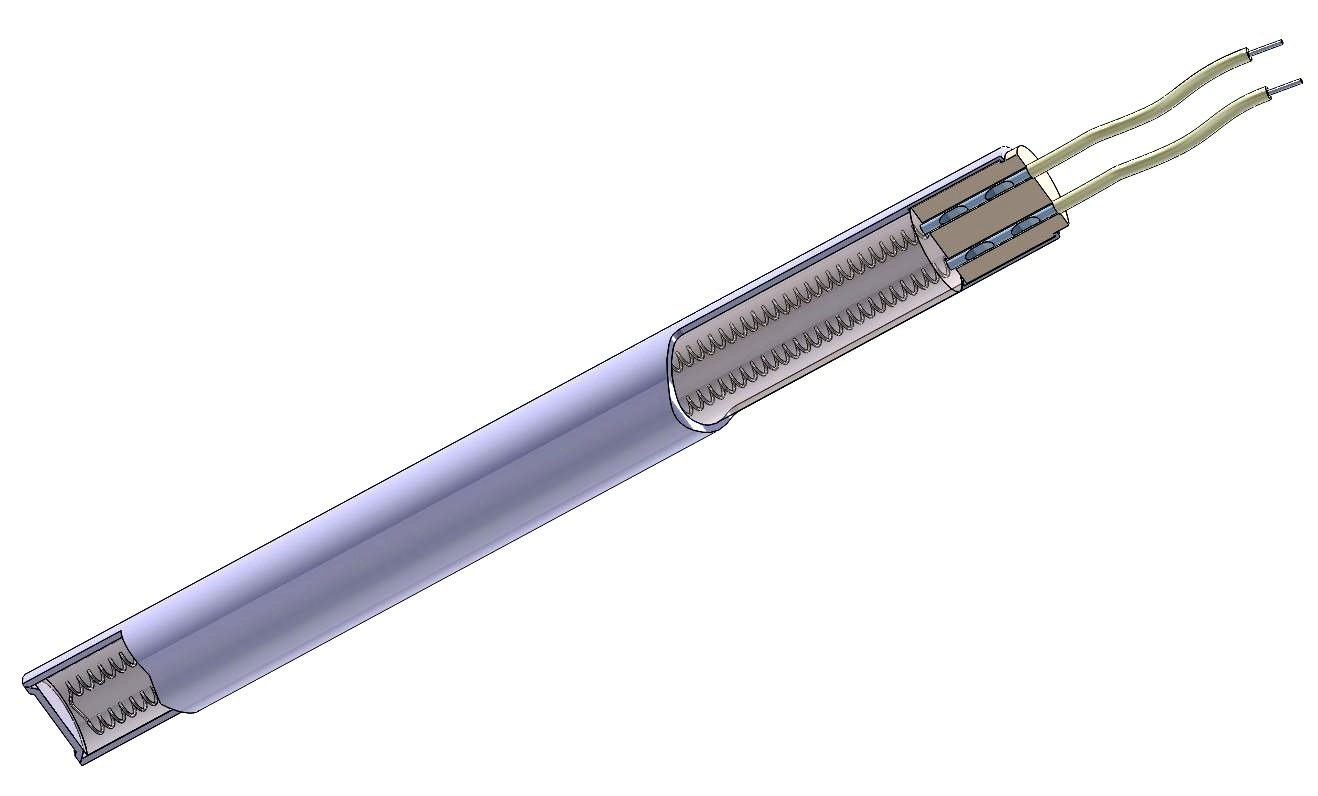

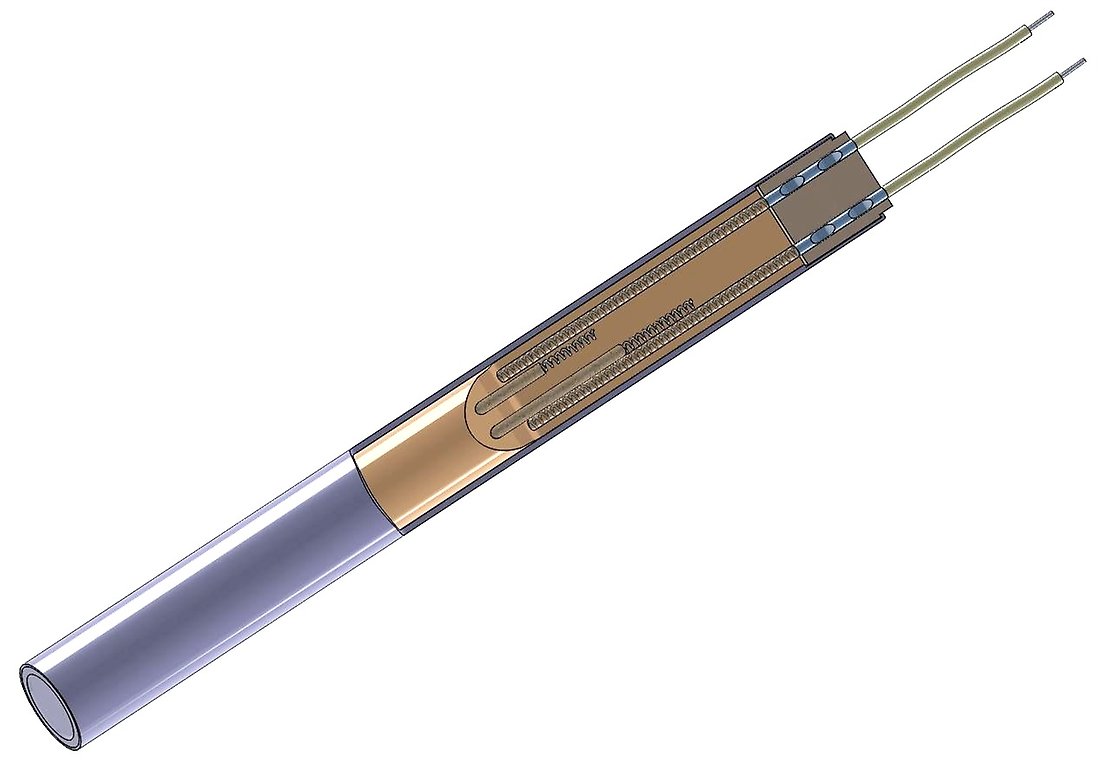

Low density cartridge heaters are used for lower temperatures and low surface loads. Resistive coils are placed in longitudinal grooves of ceramic bodies, and afterwards bodies are placed in stainless steel tubes. Tubes are filled with MgO, thus providing optimum heat transfer and reliability at reasonable price. Although, this is old and outdated solution, low density cartridge heaters are still in use for all not too demanding aplications. We produce low density cartridge heaters as per customers request and wide stock of raw materials enables us to answer to almost every request in short period of time. For energy saving and longer life time of the heater, it is advisable to bore holes with a tolerance of H7.

APPLICATIONS

- Heating of tools and machine parts

- Packaging machines

- Shoe machine industry

- Braking systems

- Compressors

- Towel dryers

- Coffee machines

Technical data

Type of heating | Heating of tools with hole |

Material | Tube material: Flange, plate or nipple material: |

Dimension | Circular cross section: Ø6mm - Ø40mm Heater length: 30mm - 4000mm Inactive length at the connection end: Min. 10mm |

Assembly | Flanges, plates, rings Threaded nipples: |

Connection | Smooth rigid pins (naked or insulated) Flexible cables for high temperatures: Additional cable protection: |

Design | Standard range or acc. to customer specification Straight cable outlet (inner contact, outer contact, contact in ceramic bead) Protective connection heads or boxes Built in thermostat (suitable for liquid heating) |

Others | Surface load: Max. 5W/cm² Diameter tolerance: -0.02/-0.08mm Insulation resistance: >5 MΩ (cold 500Vdc) |

benefits

- Easy mount and dismount

- Wide range of dimensions

- Lower demands of tolerance on the hole diameter

- Circular or square cross section

- Special connections and designs are available

- Thermostat or thermocouple can be built-in

- Economical, cost efficient