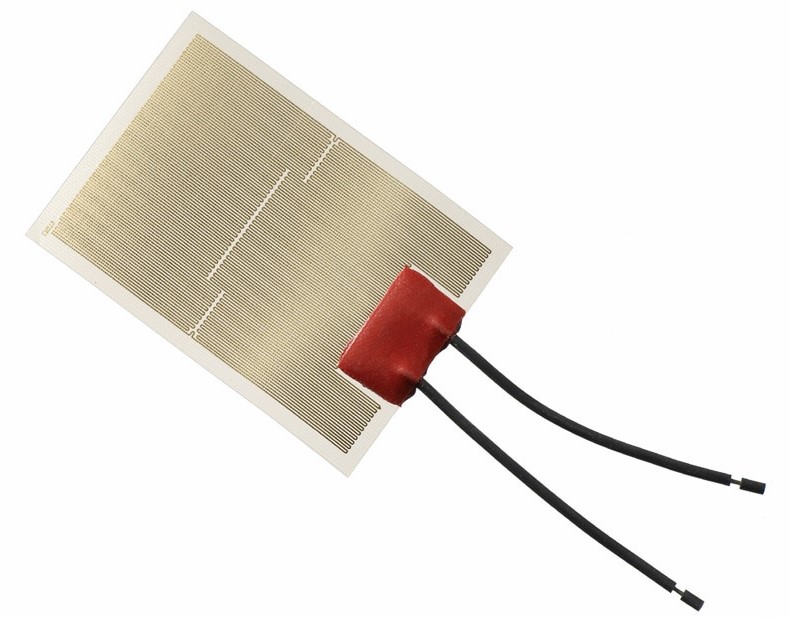

Printed foil elements

Economical and precisely manufactured

DESCRIPTION

Printed foil elements, offer many advantages, besides the material being flexible. For instance, the option of multiple circuits or multiple voltages in the same element, or the ease of positioning sensors. They have superior heat transfer and exceptionally uniform heat output, which results in a faster warm-up cycle and longer life.

We can offer foil elements within a high range of technical specifications, and insulation materials such as: Polyimide, Polyester, PEN, PET, PVC, Fibre reinforced therm plastic, etc. One side of the foil element can be furnished with an adhesive substance.

Foil elements are suitable for different applications in a wide range of areas, including communications, vehicles, monitoring, medicine, individual comfort heat, domestic heating, etc.

APPLICATIONS

- Rearview mirror heaters

- Underfloor heating

- Bathroom mirror heaters

- Preventing ice and condensation

- Refrigeration, evaporation systems

- Medical and laboratory instruments

- Hand grip heaters, handles on chainsaws

- Water bed heaters

- Heating cabinets for food

- Diesel filter heaters

- Wind screen wiper heaters

- Photographic equipment, lens heaters

- Keyboard heaters, LCD displays

Technical data

Type of heating | Air heating |

Material | Polyimide (-60°C / 200°C) |

Dimension | Acc. to customer specification |

Assembly | Adhesive |

Connection | Cables, tab terminals |

Design | Many types of configurations to fit the size and shape required |

Others | Voltage: Single or three phase |

Benefits

- High and low temperature range

- Good chemical resistance

- Very thin and flexible, space saver

- Soldered components possible

- Low weight, possible small sizes

- Long duration product

- Easy assembly, self adhesive film

- Precizely distributed wattage

- Economical, cost efficient