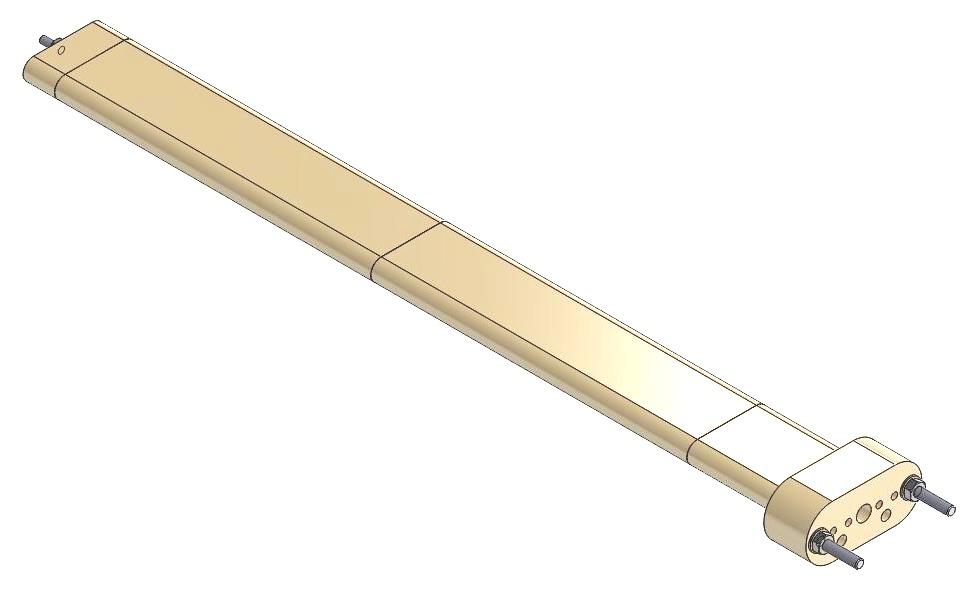

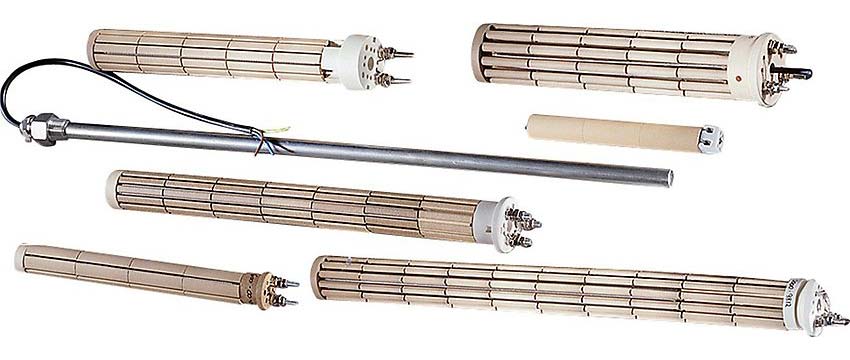

Ceramic elements

For direct air heating or indirect liquid heating

DESCRIPTION

Elektrotermija produces a wide range of different heaters on ceramic bodies. Resistance coils are placed in longitudinal holes or grooves on oval, rectangular, hexagonal... ceramic bodies or suspended on ceramic bearers. Great advantage is possibility of replacing of the element without emptying container. In such cases elements are placed in protective tubes. Ceramic elements are also used in applications when increased wall thickness of the tube due to heavy pressure stresses is required. Heat is transferred by radiation, conduction, convection or forced convection.

APPLICATIONS

- Indirect heating of liquids

- Electrical water heaters, boilers, containers, tanks

- Industrial baths, galvanic baths

- Industrial furnaces

- Oil pre-heaters, duplicators, reactors

- Air pre-heaters, dryers, fans, hot air guns

- Bakery and bread ovens, steam generators

- Storage heaters

Technical data

Type of heating | Indirect - liquid |

Material | Cordierite |

Dimension | Standard range or acc. to customer specification Heater diameter: Ø13-Ø64mm |

Assembly | Mounted into protective tube |

Connection | M3, M4, M5, M6, tab terminals, round pins, nickel wires, connection wires with ceramic beads or silicon rubber hose |

Design | Standard range or acc. to customer specification Different shapes: Round, sectional, flat, brick, flexible, with ceramic bearers |

Other | Voltage: Single phase, 2-phase, 3-phase, Max. 480V |