Indirect immersion heaters

Can be changed without discharge of the liquid

DESCRIPTION

These immersion heaters are designed for indirect heating of liquids (water, oils, emulsions) in tanks or vessels for applications in every condition, especially heavy duty. Beside the standard types we can supply special types of heaters as per costumer's demands in short terms and without quantity limitations.

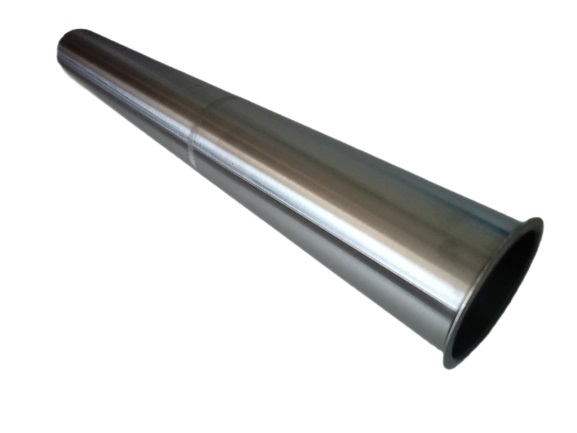

Heaters consists of ceramic cartridge placed in stainless steel protective tube. It means that the ceramic cartridge is separated from the liquid. Protective tubes can be installed in tanks in two ways: direct welding to the wall of the tank, or by flange connections (using flat or threaded flanges welded at the end of tube). Electric contacts can be protected with caps, housings or boxes. On protective caps there are cable glands for power cables.

The main advantage is in fact that ceramic cartridge can be replaced without removing tube with flange from the housing of the tank or vessel. This enables that when changing heater, there is no need to take out liquid from housing.

APPLICATIONS

- Preheating of oil in gearboxes and hydraulic oil

- Various types of vessels, tanks, reserviors, containers

- Heating of fluids in electroplating baths

- Heating of water, oils, emmulsions

- Heating of acids and aggressive fluids

- Degreasing baths

- Food industry

Technical data

Type of | Liquid heating |

Material | Tube material: Flange material: Protective cap material: |

Dimension | Diameter of tube: Ø33.7, Ø38, Ø50.8, Ø60, Ø70mm Ceramic cartridge: Ø30, Ø32, Ø46, Ø54, Ø64mm Threaded flange: G1¼", G1½", G2", G2¼", G2½ |

Assembly | Tube is welded to the wall of the tank For vertical installation, resistance coil should be skewed, which protects coil from loosening and falling due to own weight. For horizontal installation, it is recommended that protective tube with heater should be placed in vessel's bottom zone. Heater must be always immersed into liquid. |

Connection | Cable: Acc. to customer specification Cable gland: Pg11, Pg13.5, Pg16, M20x1.5 Protective cap: |

Design | Standard range or acc. to customer specification With sectional ceramic heater inside tube One, two, three or more tubes on one flange |

Others | Voltage: Single phase, 2-phase, 3-phase Max. 500V Operating pressure: Max. 6 bar Protection class: IP55 or IP66 Regulation: External thermostat |

Benefits

- Resistant to mechanical damage

- Changing the heater without removing the tube

- No need to take out liquid from tank

- Compact and robust design

- Long life product

- Dimensions, materials and power upon request