HALOGEN IR ELEMENTS

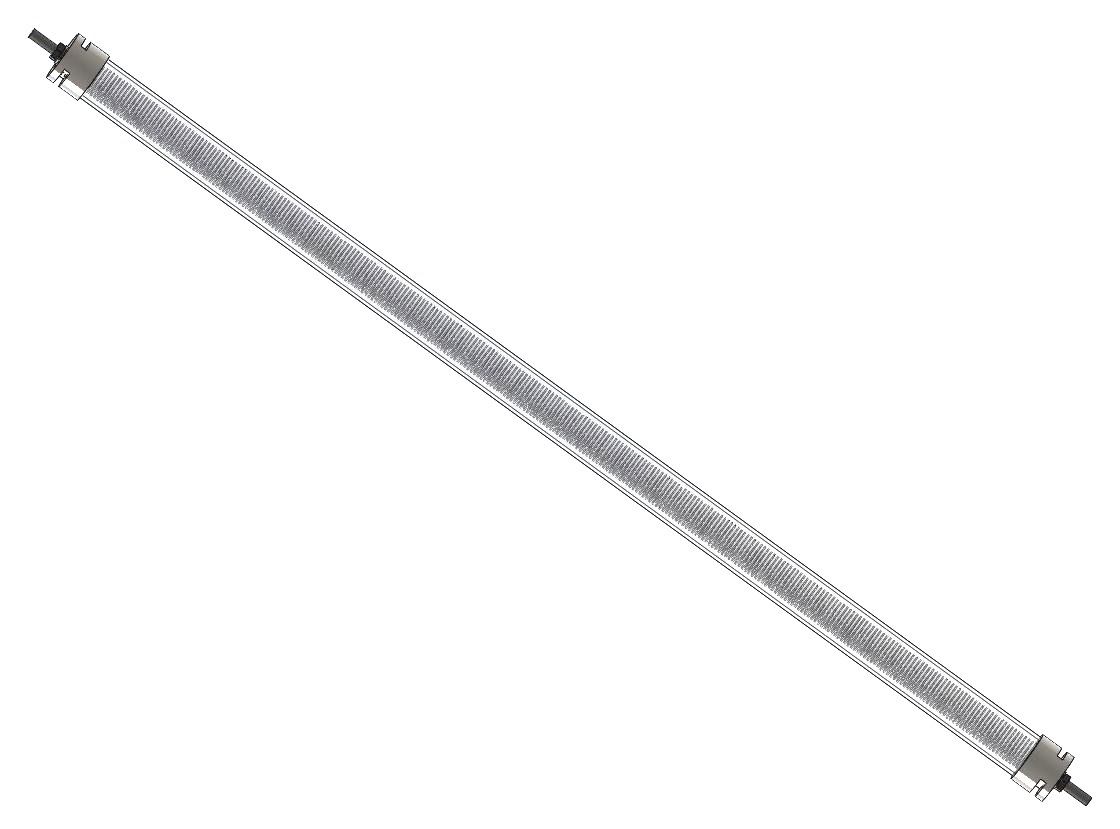

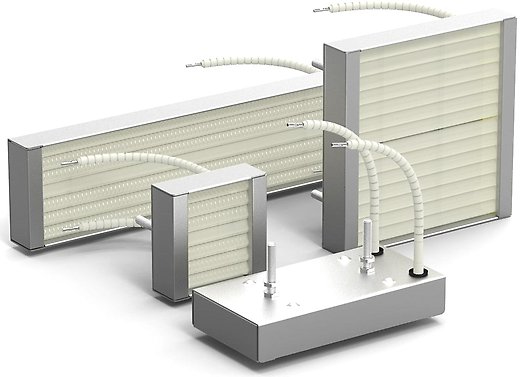

Infrared heating lamps, short wave

DESCRIPTION

Halogen infra-red elements have tungsten coil filament supported by quartz tube and protected by halogen gas. These IR lamps can reach up to 2500°C. Quartz tungsten infra-red elements have tungsten coil (or porcupine or star) filament supported by quartz tube and can reach up to 1500°C. These elements provide instant heat-up for fast moving or intensive industrial processes such as plastic industry. These elements produce a constant level of infrared radiation through the lamp lifetime. Their benefits for industrial purposes include fast heat transfer, high efficiency, direct response to power control and light weight.

APPLICATIONS

- PET bottle blowing and laminating

- Softening of plastics

- Curing for glue and printing ink

- Car painting, preheating before painting

- High temperature sterilisation

- Food baking and heating preservation

- Industrial production oven

- Drying of paper, wood, laquer, etc.

- Synthesis cable production

- Beauty apparatus

Technical data

Type of heating | Infrared radiation - short wave |

Material | Quartz glass with halogen |

Dimension | Standard range or acc. to customer specification Single tube diameter: Ø10mm Tube length: 200, 250, 300, 350, 400, 450, 500, 550, 600, 650, 700, 750, 800mm |

Assembly | Free standing in the air Lamps with round terminal end: Mounting using a R7s ceramic holder |

Connection | SK15 - square ceramic terminal end with 200mm heat resistant wire R7s - round ceramic terminal end |

Design | Filament winding style: Outer tube structure: Single tube or twin tube Connection at one or two ends Surface of quartz tube: |

Others | Wave length: 0.75-2.00 μm Accessories: Reflector type RAS, R7s ceramic holder, Steel base holder for SK15 square ceramic |

Benefits

- Resistance to high temperatures

- Resistance to sudden heating and cooling

- High efficiency and energy saving

- Compactness and light weight

- Fast heat transfer, short reaction time

- Direct response to power control

- Heating penetration deep under surface

- Can be used in vacuum and air flow environments